Transient Liquid Phase Soldering (TLPS) preforms utilize a unique composite structure, using the same processes and equipment as conventional soft solder to create lead-free solder joints with a high melting point (>400°C). Their soldering reliability rivals that of silver sintering. TLPS preforms offer low cost and high-temperature resistance, resolving the industry's pain points with high-temperature interconnect materials and are the best choice for leading customers.

Advantages of TLPS preforms:

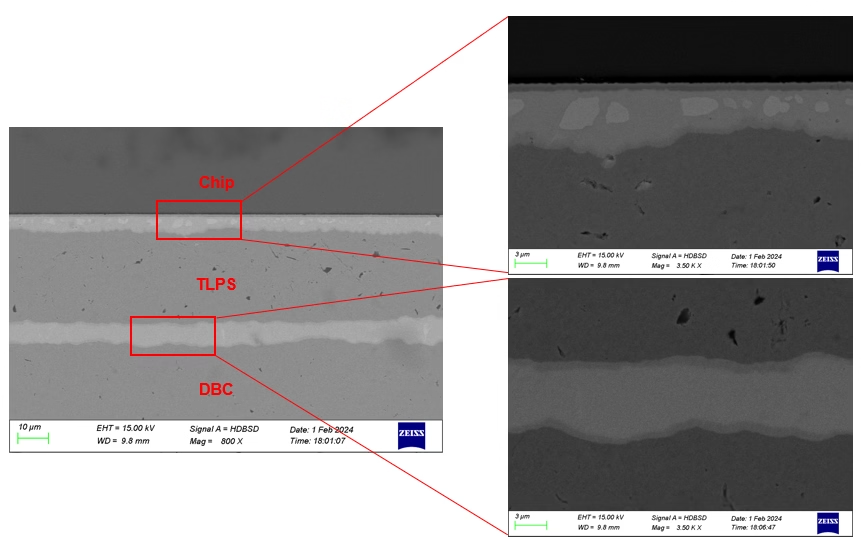

Microstructure of TLPS solder joint with full IMC

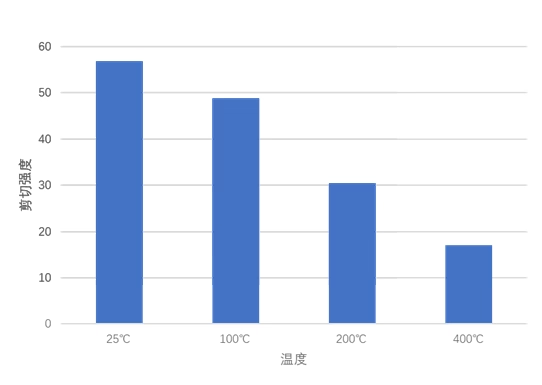

Shear strength of TLPS solder joints at different temperatures

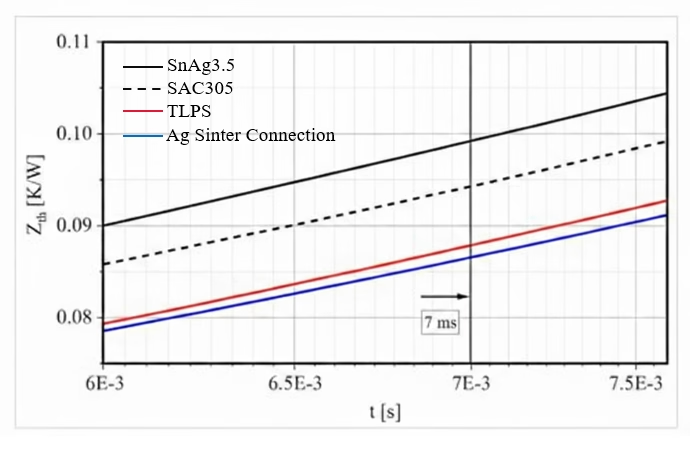

Comparison of thermal resistance of various solders

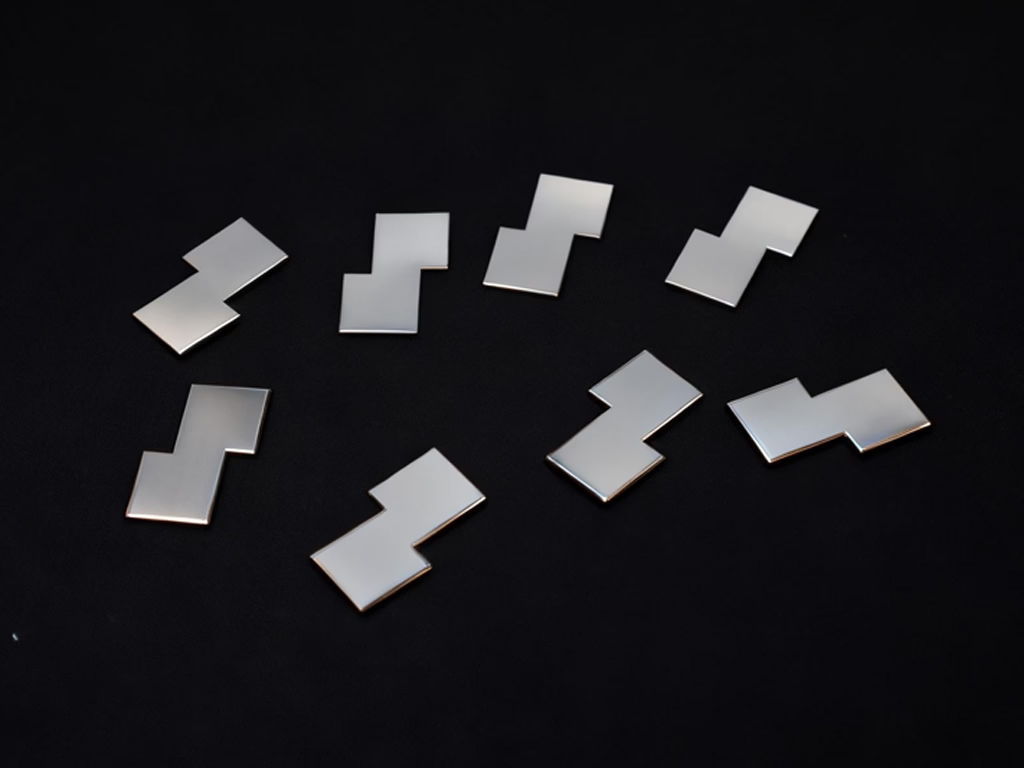

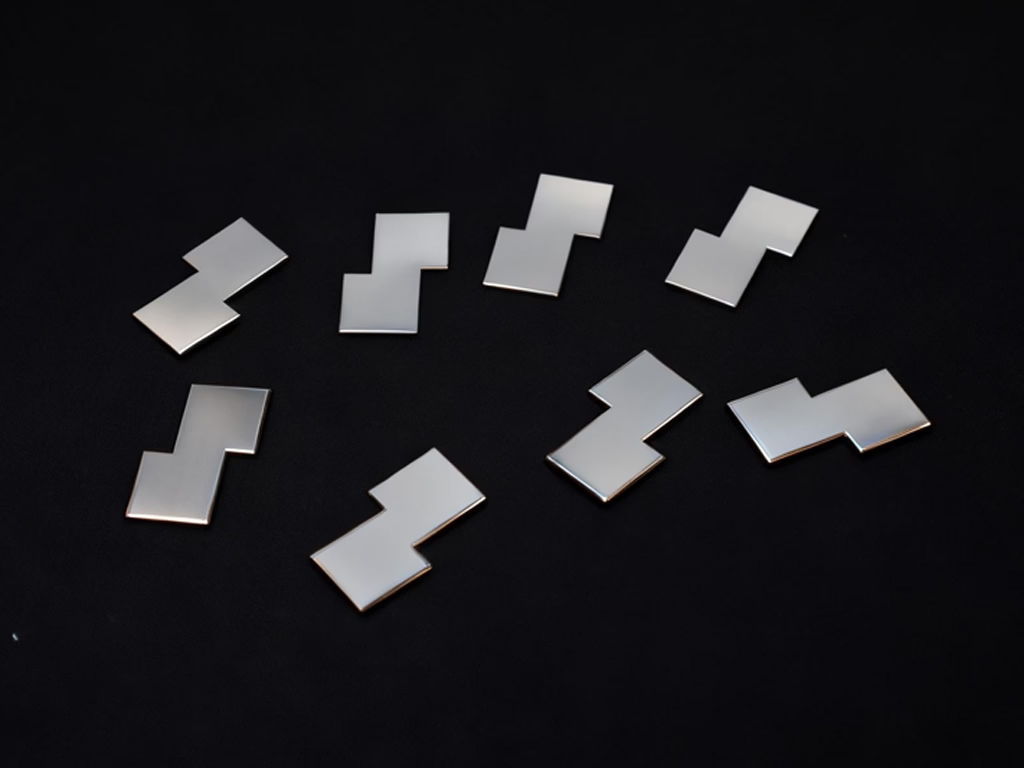

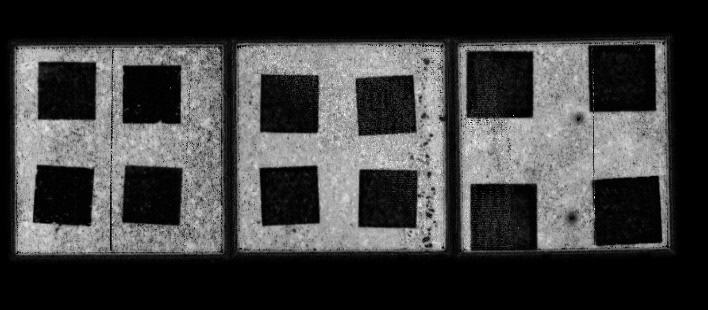

Chip soldering for various backside metallization types and die sizes (1)

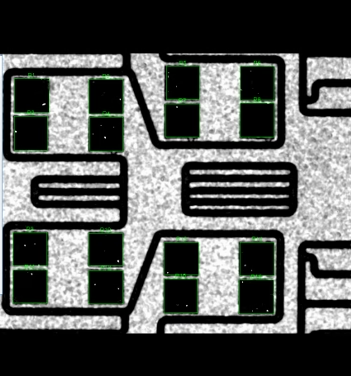

Chip soldering for various backside metallization types and die sizes (2)

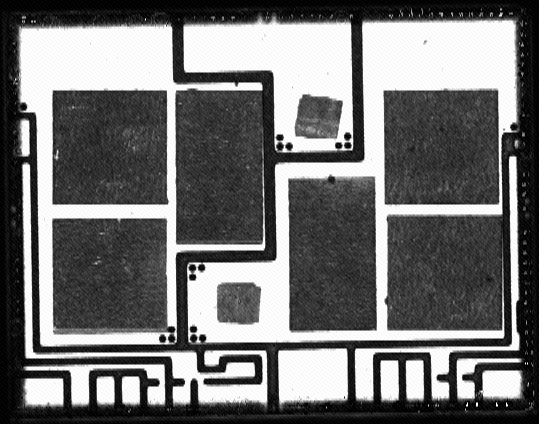

Chip soldering for various backside metallization types and die sizes (3)